Additional information

| Weight | 6 lbs |

|---|

| Your Cart |

0 items - $0.00 |

Check Out |

The EDM 700/800 monitors have been installed in thousands of cockpits, helping make every flight safer. Our compact reliable readout is coupled with our high quality grounded probes add up to an unbeatable EDM value. Add almost any option you can think of, including fuel flow, temp, and pressure senders. See our option list below. Think of the EDM 700 as your personal flight engineer. It’s always there, working in the background, constantly watching over your engine while you concentrate on flying the aircraft. You can make an entire flight without ever pushing a button, if you so choose. Yet your EDM-700 will be monitoring your engine parameters three times a second and will warn you instantly if any parameter exceeds the programmed limit.

View the EDM 700/800 Training videos

Leaning is accomplished quickly and automatically using the LeanFind™ procedure. With the EDM it is now possible to have substantially more diagnostic information available to you in a timely and usable manner.

Accuracy and Resolution, are two of the most misunderstood terms in instrumentation. Because an instrument displays 1 degree increments (resolution) does not mean it is accurate to 1 degree. JPI’s accuracy comes from its linearized thermocouples. Other’ put and estimating straight line through the center of the thermocouple calibration “S” curve. With this method the instrument is accurate at only three points along as the the straight line crosses the “S” curve. Therefore errors of +/- 10′ are quite possible while still displaying in 1degree resolution. Our competition is advertising +/- 1/2′ accuracy at full scale. This would mean that =/-1/2′ of 2000′ (full scale) is +/- 10′; there is a big difference. JPI has found nothing in the Aviation market that compares to our linearized accuracy.

Typical Customer Installation:

Dimensions:

EDM-700 – 2.5 x 2.5 x 8″ with 2 1/4 bezel, incl connector.

Specifications:

FAA Approved under TSO-C43B, DO-160C, DO-178B Level C & STC, SA 2586 NM

Size

2-1/4 in panel mount 7.5 deep. Weight: 1 LB.

Standard Functions

LeanFind, EGT/CHT, Shock Cooling, Voltage, Differential EGT, Normalize, Long term data module for Data Logging.

Optional Functions

Fuel Flow, Oil Temperature, Turbine Inlet (TIT) 1 & 2, Outside Air (OAT), Induction Air (Carburetor) IAT, Compressor Discharge (CDT).

The EDM 700 automatically accommodates both 14 and 28 volt electrical systems.

TSO C43b, Temperature Indicator EGT-701 14.5 oz ./ 0.9 lbs

EGT probe MM-111 2.0 oz. each / 0.125 lbs

CHT probe 5050 1.5 oz. each / 0.094 lbs

Wire P.N. WK.-24 Harness 8 ft. 14.0 oz. each / 0.88 lbs

RPM 1.5 oz / .094 lbs

There are no field adjustments and or calibration requirements for the EDM 700 series instrument after initial installation. ICA is not required. Maintenance of nonfunctioning or malfunctioning components is limited to removal and replacement of JPI factory supplied new or repaired components as described in the troubleshooting section of the installation instructions.

Standard Functions:

EDM-700: LeanFind, EGT/CHT, Shock Cooling, Voltage, Differential EGT, Normalize,

Long term data module for Data Logging

Optional Functions:

EDM-700:Fuel Flow, Oil Temperature, Turbine Inlet (TIT) 1 & 2, Outside Air (OAT), Induction Air (IAT), Compressor Discharge (CDT), Oil Pressure, RPM, and Carb.

$0.00

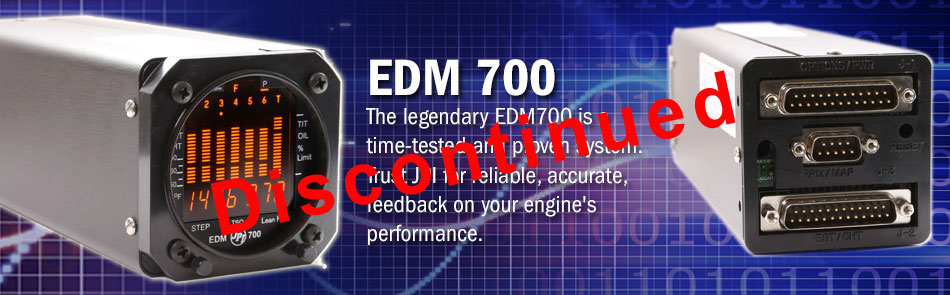

Please note: The EDM700 is Discontinued but still supported.

The Engine Data Management 700 system is the most advanced and accurate piston engine-monitoring instrument on the market. Using the latest microprocessor technology, the EDM will monitor up to twenty-four critical parameters in your engine, four times a second. Learn more about the EDM700 below:

Out of stock

| Weight | 6 lbs |

|---|

by mtv » Tue May 13, 2008 4:31 pm

I have a lot of experience in a half dozen airplanes with the EDM 700 series gauges.

What are you trying to replace, first of all? CHT/EGT? Which of those is actually REQUIRED equipment in your airplane? If neither is required equipment on the equipment list, then you can use an instrument which isn’t approved for primary information, if that matters.

In any case, the 700 series can be equipped with a fuel flow transducer, and this combination is just a great addition to any airplane. If you need primary information, then I’d opt for the 711, but not sure if the 800 would be preferable. I’ve no experience with the 800, but looking at the information on their web site, I don’t see a lot of additional information that would be all that useful.

JPI guages have simply the best viewability of any of these types of instruments, in my opinion, and I wouldn’t use anything else.

MTV

I chose the EDM 700 over the UBG-16 for the simple reason that the instrument has all the features I desire. I find that the faster probe response combined with the “overlean” graph capabilities make the EDM 700 simply better! Getting free software with an actually functioning data recording option is just the icing on the cake.

I was headed back to the Pacific Northwest in my 89’Mooney 201 from southern Florida. Shortly after takeoff the EDM 700 was showing the EGT on cylinder #1 was running 240′ hotter than the lowest EGT reading of the other 3 cylinders.#1 CHT was slightly south of 385′. I watched it closely as I proceeded to Biloxi. I concluded it was likely a plugged fuel injector. When I landed I removed, cleaned and reinstalled the fuel injector. Problem pin pointed and solved by the 700. Excellent investment for any aircraft

Admin (verified owner) –

by mtv » Tue May 13, 2008 4:31 pm

I have a lot of experience in a half dozen airplanes with the EDM 700 series gauges.

What are you trying to replace, first of all? CHT/EGT? Which of those is actually REQUIRED equipment in your airplane? If neither is required equipment on the equipment list, then you can use an instrument which isn’t approved for primary information, if that matters.

In any case, the 700 series can be equipped with a fuel flow transducer, and this combination is just a great addition to any airplane. If you need primary information, then I’d opt for the 711, but not sure if the 800 would be preferable. I’ve no experience with the 800, but looking at the information on their web site, I don’t see a lot of additional information that would be all that useful.

JPI guages have simply the best viewability of any of these types of instruments, in my opinion, and I wouldn’t use anything else.

MTV

Admin (verified owner) –

I chose the EDM 700 over the UBG-16 for the simple reason that the instrument has all the features I desire. I find that the faster probe response combined with the “overlean” graph capabilities make the EDM 700 simply better! Getting free software with an actually functioning data recording option is just the icing on the cake.

Gary Jones –

I was headed back to the Pacific Northwest in my 89’Mooney 201 from southern Florida. Shortly after takeoff the EDM 700 was showing the EGT on cylinder #1 was running 240′ hotter than the lowest EGT reading of the other 3 cylinders.#1 CHT was slightly south of 385′. I watched it closely as I proceeded to Biloxi. I concluded it was likely a plugged fuel injector. When I landed I removed, cleaned and reinstalled the fuel injector. Problem pin pointed and solved by the 700. Excellent investment for any aircraft