Additional information

| Weight | 5 lbs |

|---|

| Your Cart |

0 items - $0.00 |

Check Out |

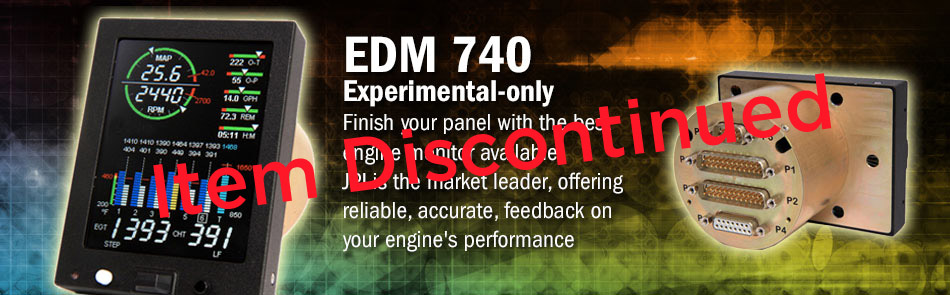

Please note: This Item Is No Longer Available. The Engine Data Management 740 experimental system is the most cost effective, advanced and accurate piston engine-monitoring instrument on the market. The EDM-740 is not just another black box along for the ride. It is a Flight Engineer … a Maintenance Manager … a Backup Instrument. For the price there is nothing that gets close to it. You can almost think of the EDM-740 as your personal flight engineer. It’s always there, working in the background, constantly watching over your engine while you concentrate on flying the aircraft. You can make an entire flight without ever pushing a button, if you so choose. Yet your EDM-740 will be monitoring your engine parameters three times a second and will warn you instantly if any parameter exceeds the programmed limit.

–

Same as the EDM-830 plus additional Options

Now optional FUEL Level, Fuel Pressure (injected only) and Amps with shunt.

User Selectable Positions for Linear gauges.

3 year Warranty

Optional functions

CDT

IAT

CARB Temperature

TIT

Air Pressure 1000 psi

Sold as single package only

L/R-Tank Fuel Quantity ,Res or Cap. Fuel Quantity probes not included Only electronics to connect.

F-P Fuel Press W/transducer

AMP Amps w/100 amp shunt

$0.00

| Weight | 5 lbs |

|---|

Review Excerpt From “Kitplanes” 06/2010

Product Review: J.P. Instruments EDM-740

A familiar name in engine monitors unleashes an amazingly flexible all-in-one device.

J.P. Instruments has been a household name for owners of certificated aircraft, but now it is approaching the Experimental market with new vigor and, more importantly, a completely new product. Check out the EDM-740, an Experimental-only version of the company’s EDM-730 that’s both innovative and, shall we say, aggressively priced. Got your attention?

Indeed, in that base package, you’ll get most of the popular sensors. Electrical-bus current, turbine-inlet temp, carb temp and fuel pressure are optional. And while the device can read resistance or capacitance fuel-level senders, it’s up to the builder to provide them.

The 740 follows JPI’s established engine-monitor traditions of stacked EGT and CHT readouts so you can watch all cylinders at once. One great feature is that when you choose four cylinders instead of the six shown in the photo above, the bar graphs are redrawn proportionally; there are no “missing bars” with the 740, thanks very much. You can choose the order of the subordinate menu items as well.

Making It Fit

A boon for retrofitters, the EDM-740 slithers into a 3.125-inch instrument hole; the barrel is offset and the display can be turned any side up. This feature allows you to mount it near existing instruments and avoid physical interference. Minus the connectors, the 740 is a mere 2 inches deep behind the panel. The faceplate is 4.23 inches tall and 3.195 inches wide.

Key features include user-defined redlines and alarms and a large single-line display that magnifies the values of other indications; you scroll through the display’s choices with the STEP button. If you have ever used a conventional JPI engine monitor, the 740’s methodology will be immediately familiar. Also on the front panel is the LF button, for Lean Find. In default mode, when you press LF once, the term ROP will appear, which means it’s entering the lean-find mode, expecting you to run the engine rich of peak EGT. (If you press and hold both buttons, you can select LOP for lean-of-peak operations; you can make this your default setting if you prefer.) In Lean Find, the monitor watches the EGTs rise and notes the first and last to peak. Once it has found peak, the bottom display line changes to show the current fuel flow and the temperature delta from peak of the controlling cylinder, all as an aid to leaning. In the LOP mode, the EGT bars form an “icicle” layout, descending from the top line, to show how far each cylinder is lean of peak EGT.

The EDM-740 also features an engine-power calculator, and here it’s done correctly: Rich of peak it uses mass airflow (manifold pressure x rpm, roughly), but lean of peak it uses fuel flow to calculate power.

In the Air

Lance Turk, designer of the first all-in-one engine monitor, the Vision Microsystems VM-1000, is now JPI’s new-product guy. I had a chance to sample the EDM-740 in Turk’s Glasair I. Even cross-cockpit (Turk has the unit mounted in the small left subpanel) the 740’s display is clear and legible right down to the smallest menu item. Notable are the fast-responding probes—during the several engine-leaning cycles we tried, the EGTs immediately followed movement of the mixture control, and the Lean Find function looked stable and easily digestible to a pilot who is busy doing other things (like flying). And those who want to track engine health will be excited to learn that the 740 includes integral data logging—it can absorb data at 6-second intervals for some 200 hours.

My exposure suggests that the EDM-740 will be an excellent choice for builders trying to squeeze the most into a tight panel and, particularly, for those updating older panels to the latest in electronic engine monitoring.

For more information, call 800/345-4574 or visit http://www.jpinstruments.com.

Will the EDM 740 be powered by 12 volts or 24 volts?

Admin –

Review Excerpt From “Kitplanes” 06/2010

Product Review: J.P. Instruments EDM-740

A familiar name in engine monitors unleashes an amazingly flexible all-in-one device.

J.P. Instruments has been a household name for owners of certificated aircraft, but now it is approaching the Experimental market with new vigor and, more importantly, a completely new product. Check out the EDM-740, an Experimental-only version of the company’s EDM-730 that’s both innovative and, shall we say, aggressively priced. Got your attention?

Indeed, in that base package, you’ll get most of the popular sensors. Electrical-bus current, turbine-inlet temp, carb temp and fuel pressure are optional. And while the device can read resistance or capacitance fuel-level senders, it’s up to the builder to provide them.

The 740 follows JPI’s established engine-monitor traditions of stacked EGT and CHT readouts so you can watch all cylinders at once. One great feature is that when you choose four cylinders instead of the six shown in the photo above, the bar graphs are redrawn proportionally; there are no “missing bars” with the 740, thanks very much. You can choose the order of the subordinate menu items as well.

Making It Fit

A boon for retrofitters, the EDM-740 slithers into a 3.125-inch instrument hole; the barrel is offset and the display can be turned any side up. This feature allows you to mount it near existing instruments and avoid physical interference. Minus the connectors, the 740 is a mere 2 inches deep behind the panel. The faceplate is 4.23 inches tall and 3.195 inches wide.

Key features include user-defined redlines and alarms and a large single-line display that magnifies the values of other indications; you scroll through the display’s choices with the STEP button. If you have ever used a conventional JPI engine monitor, the 740’s methodology will be immediately familiar. Also on the front panel is the LF button, for Lean Find. In default mode, when you press LF once, the term ROP will appear, which means it’s entering the lean-find mode, expecting you to run the engine rich of peak EGT. (If you press and hold both buttons, you can select LOP for lean-of-peak operations; you can make this your default setting if you prefer.) In Lean Find, the monitor watches the EGTs rise and notes the first and last to peak. Once it has found peak, the bottom display line changes to show the current fuel flow and the temperature delta from peak of the controlling cylinder, all as an aid to leaning. In the LOP mode, the EGT bars form an “icicle” layout, descending from the top line, to show how far each cylinder is lean of peak EGT.

The EDM-740 also features an engine-power calculator, and here it’s done correctly: Rich of peak it uses mass airflow (manifold pressure x rpm, roughly), but lean of peak it uses fuel flow to calculate power.

In the Air

Lance Turk, designer of the first all-in-one engine monitor, the Vision Microsystems VM-1000, is now JPI’s new-product guy. I had a chance to sample the EDM-740 in Turk’s Glasair I. Even cross-cockpit (Turk has the unit mounted in the small left subpanel) the 740’s display is clear and legible right down to the smallest menu item. Notable are the fast-responding probes—during the several engine-leaning cycles we tried, the EGTs immediately followed movement of the mixture control, and the Lean Find function looked stable and easily digestible to a pilot who is busy doing other things (like flying). And those who want to track engine health will be excited to learn that the 740 includes integral data logging—it can absorb data at 6-second intervals for some 200 hours.

My exposure suggests that the EDM-740 will be an excellent choice for builders trying to squeeze the most into a tight panel and, particularly, for those updating older panels to the latest in electronic engine monitoring.

For more information, call 800/345-4574 or visit http://www.jpinstruments.com.

Norbert Steinwandter –

Will the EDM 740 be powered by 12 volts or 24 volts?

Craig Peyton –

Thanks for your question..The EDM-740 for 14V and 28V systems. (Use a 5 AMP circuit breaker)